- Zainab Zakaryia Ali

- zainab.ali@su.edu.krd

- 0750 481 5025

- Thesis, MSc

-

Nature-like designs inspired designers to adapt them in real-life applications due to their strength and optimal mechanical properties. In the current study, irregular Voronoi structures were prepared through using of Rhinoceros 7Grasshopper software. Both normal and elongated Voronoi designs (based on the columnar joints that exist naturally) were designed, having three separate models per each, homogeneous, gradient I, and gradient II are based on homogeneity and having a core inside the samples. Stereolithography (SLA) three-dimensional (3D) printing was used to fabricate biopolymer Plant-based materials to be prepared for mechanical testing. Generally, the experimental results showed that the proposed Voronoi designs with elongated structures have better mechanical properties. They are about 21% superior to the normal Voronoi structures in terms of resisting deformation and approximately 30 % in energy absorption. Hence, these designs are promising topologies for future applications. Moreover, the failure mode of the six structures occurred due to the collapse in three stages: the cells’ strut fracture, cell collapse, and eventually, fracture growth. In regard to the designed models, the homogeneous model type showed a higher stiffness and ultimate strength while the gradient I model exhibited a higher Young's modulus. Furthermore, the homogeneous and gradient II models showed a great energy absorption property. Besides, the gradient II model possessed the poorest mechanical properties due to its weak geometry design. Hence, this model is not preferred in lightweight-to-strength applications.

- Erbil Technical Engineering College

- Mechanical and Energy Engineering

- Applied Mechanic

- Kurdistan Wns HamaAli

- kurdistan.hamaali@epu.edu.iq

- 0750 746 4633

- thesis_KurdistanWns_Final

-

Abstract

The integration of Five Generation networks and Wireless Sensor Networks is crucial for the new area of the Internet of Things, which is used for a wide range of applications. Such as: daily living, manufacturing, health care and transportation, etc. Wireless sensor networks consist of small sensor nodes with limited energy. Such nodes have the ability to monitor the physical conditions and communicate information among the nodes without the requirement of the transmission medium. Wireless Sensor Networks are autonomous and are distributed in space. Due to the absence of central authority and random deployment of nodes in the network, Wireless Sensor Network is prone to security threats.

Wireless Sensor Network are vulnerable to so many network layer attacks such as wormhole and replay attacks. Also, Energy conservation is critical in Wireless Sensor Network because the main source of power for sensor nodes is battery with a limited energy. It cannot be easily replaced or recharged. Therefore, power saving is essential to increase the lifetime of sensor nodes. Attackers compromise the internal sensor nodes from which they launch attacks. By sending malicious information, attackers may decrease the sensor nodes’ lifetime from years to days and have a severe impact on the energy of the sensor network. Therefore, The larger amount of energy consumed by sensor nodes during the illegal packet transmission by the attackers. Our work proposed a Detect and Compare Packet Nonce (DCPN) algorithm and Packet Count Detection (PCD) algorithm for Wireless Sensor Networks. These algorithms efficiently identify and isolate attacks like wormhole and replay while avoiding possible service degradation like energy consumption in sensor nodes. The simulation results show that our mechanism can outperform existing techniques in terms of energy consumption and lifetime of sensor nodes. DCNP saves energy by (21.6%) per

X

hour for a wormhole attacks, whereas PCN saves up energy by (12%) per hour for replay attacks, thus increases the lifetime of the sensor node by (19.2%) per hour when using DCPN and by (12%) per hour when using PCD. Finally, the study also shows the temperature monitoring of some mobile sensor nodes. By implementing these algorithms, the temperature of the sensors can be reduced by (10C- 2.50C) per (2.5) minutes. - Erbil Technical Engineering College

- Information System Engineering

- Wireless Sensor Network(WSN)

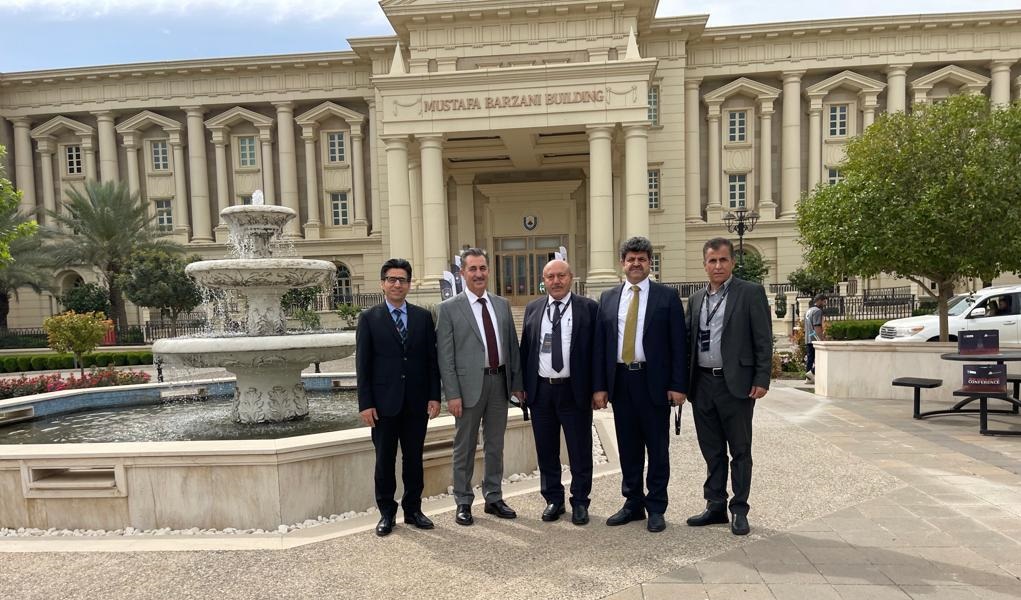

His Excellency Prof. Dr. Edrees Muhamad Tahir Harki, the Erbil Polytechnic University Rector attended “First-Ever Healthcare Simulation” Conference organized by the College of Nursing of the American University in Duhok.

Our university delegation led by Prof. Dr. Edrees Muhamad Tahir Harki, accompanied by Asst. Prof. Dr. Najib Toma Bato, theVice Rector for Scientific Affairs, Asst. Prof. Mr. Umed Arshad Hawezi, thw Erbil Technical Medical Institute Dean, and Dr. Talib Mohammed Sharif, the Dean of Mergasur Technical Institute were invited by the American University of Duhok to participate a conference dedicated to health care simulation.

In the conference, the Minister of Health of the Kurdistan Regional Government Dr. Saman Barzanji, the Minister Deputy of the Higher Education and Scientific Research Prof. Dr. Abdulfatah Abdulrazaq, a number of presidents of Kurdistan universities, members of the Kurdistan Parliament, and academic staff were present.

-

Karmand Abubakr Ahmed -

eng.karmand@gmail.com - 0750 415 4031

- Karmand Abubakr -MSc thesis

-

In this study, a high temperature tribometer machine of pin-on-disc was designed and manufactured to examine the wear characteristics of 2024 and 7075 aluminium alloys at different wear conditions such as temperature, load, and sliding distance. The wear experiments were

carried out in a dry sliding condition at temperatures ranging from 25 to 225 °C, loads of 10, 20, and 30 N, and sliding distances of 1570, 2356, and 3141 m, with constant sliding speed of 2.6 m/s throughout the testing. The results showed that when the temperature increases, the wear due to volume loss also increases. An increase in sliding distance and load increases the wear. The Microscopic analysis and Scanning Electron Microscope (SEM) of the specimens reveals that wear traces are mostly abrasive, with just small traces of adhesive wear visibility. Furthermore, the wear process switched from mild into delamination and subsequently to severe metal wear as the load and temperature continued to increase. Because of the softening impacts of the high operating temperature, the wear mechanism takes the form of massive removal of material in a sliding direction. Due to the higher hardness of Al7075, it has higher wear resistance and lower wear (volume loss) compared to Al2024. -

Erbil Technical Engineering College -

Mechanical and Energy -

Applied Mechanics